FlowFriend Junior

FlowFriend Junior:

• motor with protection class IP67

• energy efficient

• external controller - short-circuit proof and IP66

• 0-10V / 0-20mA / 4-24mA external control

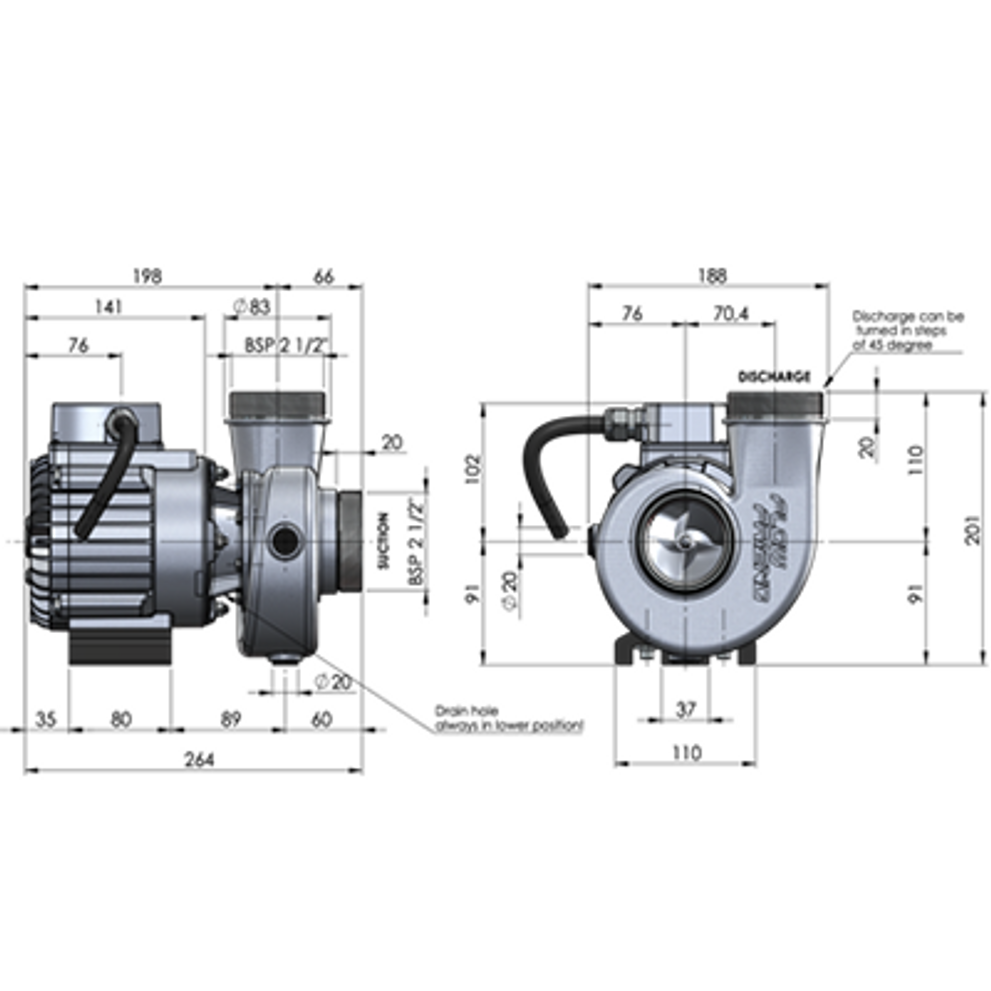

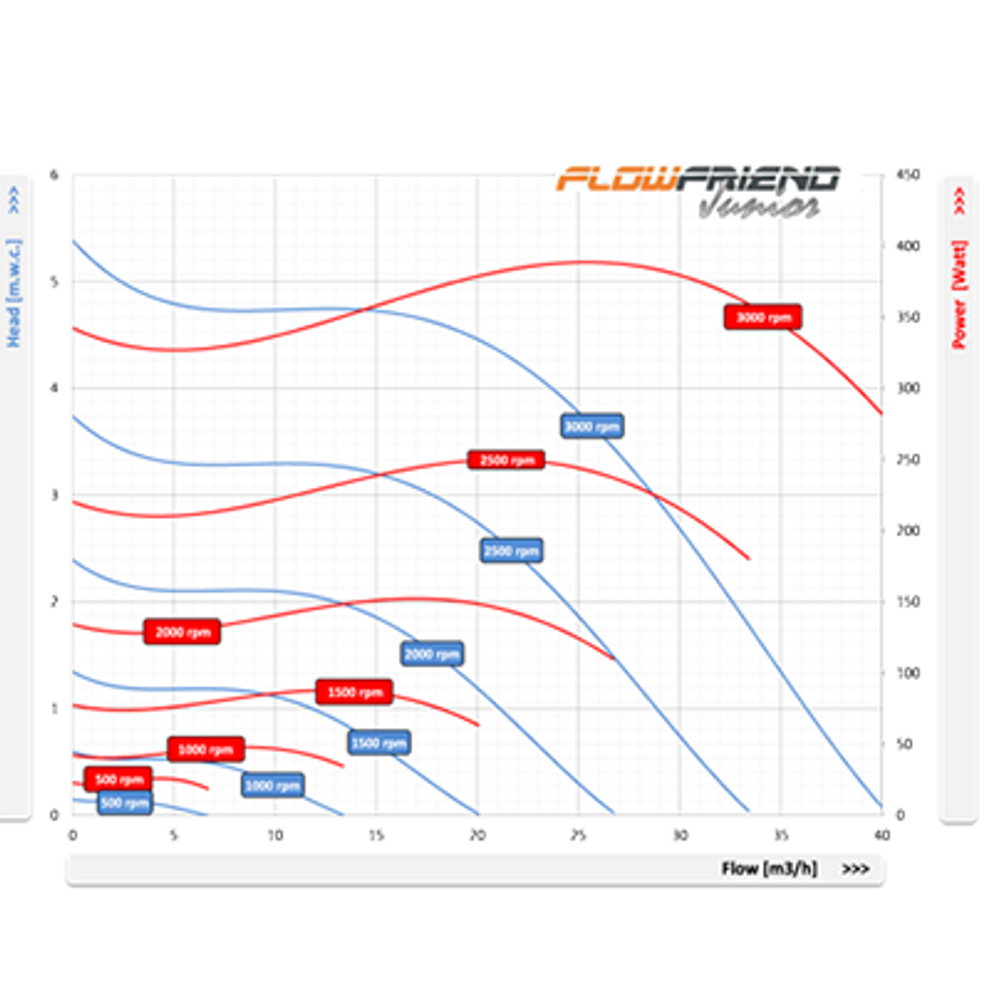

• adjustable 2-40 m3/hour / 20-370 Watt / 500-3000 rpm

• fanless - very quiet

• IE6: Latest generation permanent magnet motor (EC/BLDC)

• 5.5 meter lifting height

The main difference is that the motor and control electronics are separate. Because the pump doesn't require a cooling fan, it meets IP class 67. The electronics can be mounted in an easily accessible location and can be remotely controlled in several ways. The control cabinet, pump, and cable are fully EMC shielded.

The pump's highly efficient design remains unchanged, minimizing losses in the hydraulics, engine, and control electronics.

At full power, the maximum efficiency of the hydraulics is above 85%, the engine above 94%, and the steering above 98%. The engine complies with the latest, yet-to-be-officially released IE6 energy efficiency standard.

The Junior's hydraulics, like all other FlowFriend pumps, are made of 316 stainless steel and are of the mixed-flow type. This allows for a delivery head of up to 5.5 meters and an adjustable flow rate up to 40 m³/h, giving the pump a wide range of applications for efficient operation. The pump is fully adjustable (500-3000 rpm) via an external control system.

The control electronics

The FlowFriend is supplied with short-circuit proof control electronics and is/has as standard:

• keypad

• short-circuit proof

• internal EMC filter

• Modbus RTU

• CANopen

• analog inputs (0-10V / 0-20mA / 4-20mA)

• digital inputs

• IP66

This control also displays the power consumption. The Junior can be remotely controlled via the numerous analog and digital inputs.

The major advantage of permanent magnet motors over frequency-controlled asynchronous motors is their remarkably high efficiency at low speeds. However, they are also significantly more economical in the higher speed range.

Ingenious pump houses

A pump's hydraulics consist of the impeller and the pump housing. The FlowFriend's hydraulics are made entirely of cast 316 stainless steel. Robust, smooth, and perfectly shaped for minimal internal losses.

The hydraulics largely determine the overall efficiency of the pump and the suitability of the pump for a particular application.

Dry runner or wet runner

The FlowFriend is a dry-installed pump with a seal (dry-running). This technology is superior in terms of energy efficiency and safety compared to so-called wet-running pumps (where the pump's armature rotates in the water). Therefore, pumps with a seal are almost exclusively used in industrial applications. Because dry-running pumps have an extremely close spacing between the armature and stator, they have significantly lower energy losses during operation compared to wet-running pumps. Therefore, wet-running pumps always involve a compromise. If the distance between the stator and armature is very small, the risk of damage due to debris trapped between the armature and stator is very high. However, as the distance increases, the pump's energy losses increase quadratically.

If the stator side of a wet-running motor is damaged, direct contact between the core (with voltages above 300V) and the water is possible. Therefore, a wet-running motor is not recommended for applications where people touch or swim in the water.

Nederlands

Nederlands

Deutsch

Deutsch